Laser and traditional welding are still competing

With much faster processing speeds and higher quality, you might think laser welding would quickly take over the field. But traditional welding hangs on. And depending on who you ask and what applications you consider, it may never go away. So what are the pros and cons of each method that continue to result in a mixed market?

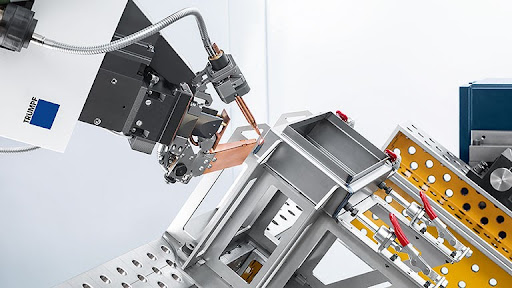

Trumpf’s Fusion Line features a laser assisted with wire to introduce more mass into the weld, bridging gaps up to 1 mm wide.

Traditional methods of welding remain popular. Broadly speaking, three types of traditional welding used in industry are MIG (metal inert gas), TIG (tungsten inert gas), and resistance spot. In resistance spot welding, two electrodes press the parts to be joined between them, large current is forced through that spot, and the electrical resistance of the part material generates the heat that welds the pieces